mixed crystal nano titania

...

2025-08-14 18:54

2566

One of the key features of the Tio2 BLR-895 range is its modular architecture, which allows for customization and scalability. Manufacturers can tailor the system to their specific needs, whether it involves simple repetitive tasks or complex processes requiring precision and reliability. The ability to upgrade and expand functionality as requirements evolve further underscores the future-proof nature of these systems.

...

2025-08-14 18:54

64

Durabo White, 24.5 per cent zinc sulphide, 51 per cent barium sulphate, 18 per cent white clay, 5.5 per cent infusorial earth.

...

2025-08-14 18:13

1876

Lithopone, a staple in the paint industry, boasts a unique blend of properties that make it an indispensable component for achieving high-quality finishes. Among its many variants, B301 and B311 stand out as two of the most sought-after types due to their specific characteristics and performance metrics. In this brief exploration, we will delve into the significance of these lithopone grades, discuss factors affecting their price lists, and highlight the role of reputable suppliers in ensuring consistent quality and availability.

...

2025-08-14 18:10

518

Titanium Dioxide A Versatile Pigment for Interior and Exterior Wall Paint Materials

...

2025-08-14 17:38

88

...

2025-08-14 17:30

2122

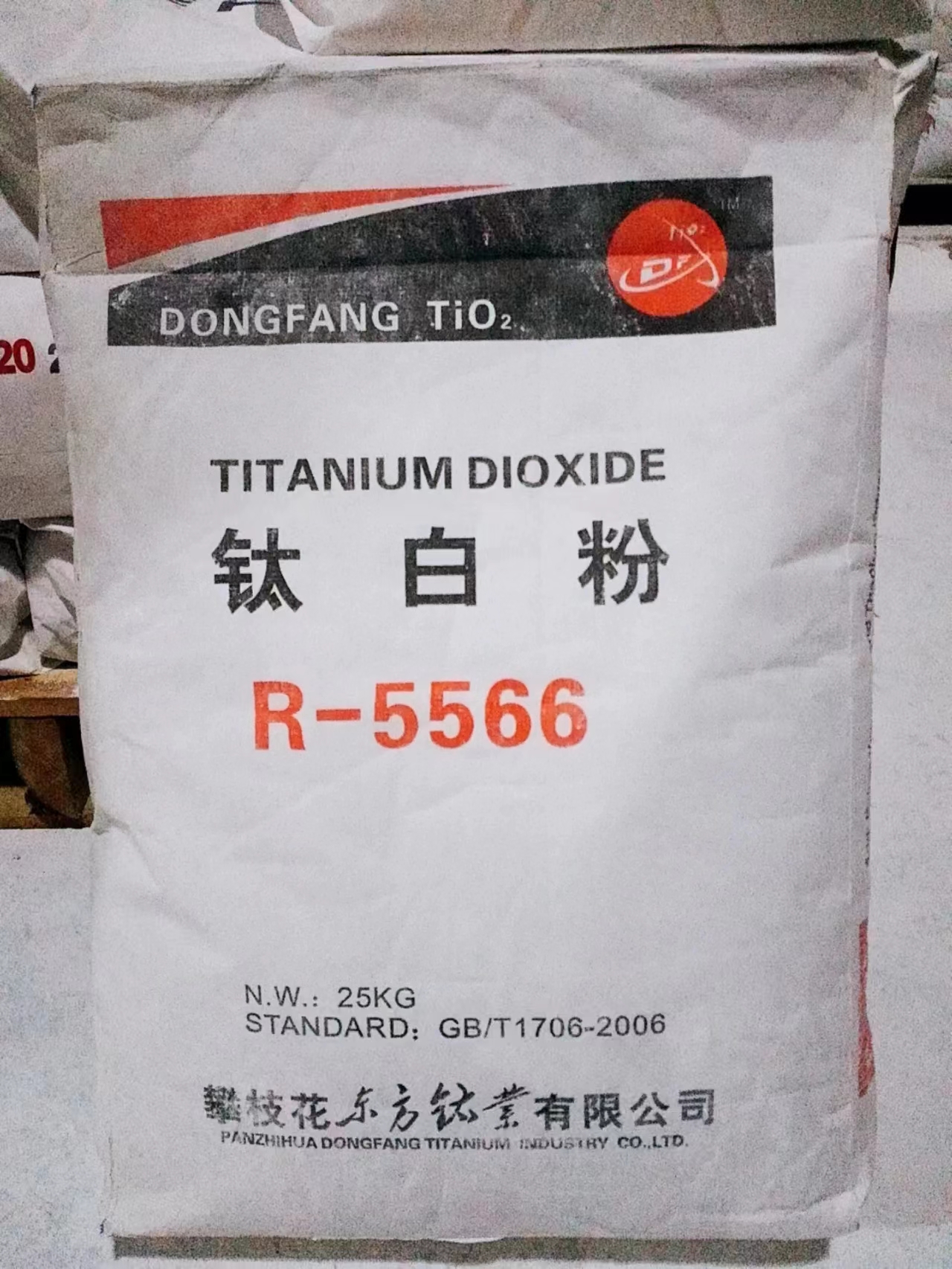

Titanium Dioxide Raw Material Tio2 Powder

...

2025-08-14 17:13

2780

Blanc de Comines, 27 per cent zinc sulphide, 70.5 per cent barium sulphate, 2.5 per cent zinc carbonate.

...

2025-08-14 16:39

1367

The Multifaceted World of Titanium Dioxide

...

2025-08-14 16:34

2345

One of the key features of the Tio2 BLR-895 range is its modular architecture, which allows for customization and scalability. Manufacturers can tailor the system to their specific needs, whether it involves simple repetitive tasks or complex processes requiring precision and reliability. The ability to upgrade and expand functionality as requirements evolve further underscores the future-proof nature of these systems.

Durabo White, 24.5 per cent zinc sulphide, 51 per cent barium sulphate, 18 per cent white clay, 5.5 per cent infusorial earth.

Lithopone, a staple in the paint industry, boasts a unique blend of properties that make it an indispensable component for achieving high-quality finishes. Among its many variants, B301 and B311 stand out as two of the most sought-after types due to their specific characteristics and performance metrics. In this brief exploration, we will delve into the significance of these lithopone grades, discuss factors affecting their price lists, and highlight the role of reputable suppliers in ensuring consistent quality and availability.

Titanium Dioxide A Versatile Pigment for Interior and Exterior Wall Paint Materials

Titanium Dioxide Raw Material Tio2 Powder

Blanc de Comines, 27 per cent zinc sulphide, 70.5 per cent barium sulphate, 2.5 per cent zinc carbonate.

The Multifaceted World of Titanium Dioxide

One of the key advantages of using nano titania in coatings is its superior UV resistance. Nano titania can effectively absorb and scatter UV radiation, providing enhanced protection against UV-induced degradation of coatings. This property makes nano titania an ideal choice for exterior coatings exposed to sunlight, such as automotive coatings, building coatings, and marine coatings.

With such a broad spectrum of utility, selecting the right barium zinc sulfate supplier becomes a matter of significant importance for manufacturers barium zinc sulphate supplier. Reliability, purity standards, consistent supply chains, and competitive pricing are all factors that must be considered when choosing a supplier. A reputable supplier should also provide comprehensive technical support and be capable of meeting stringent quality control measures to ensure that the barium zinc sulfate supplied meets the specific needs of each industrial process.

barium zinc sulphate supplier. Reliability, purity standards, consistent supply chains, and competitive pricing are all factors that must be considered when choosing a supplier. A reputable supplier should also provide comprehensive technical support and be capable of meeting stringent quality control measures to ensure that the barium zinc sulfate supplied meets the specific needs of each industrial process.

The Journal of the American Institute for Conservation (JAIC) is an international peer-reviewed periodical for the art conservation profession. The Journal publishes articles on treatment case studies, current issues, materials research, and technical analyses relating to the conservation and preservation of historic and cultural works. The topics encompass a broad range of specialties including architectural materials, archeological objects, books and paper, ethnographic materials, objects, paintings, photographic materials, sculpture, and wooden artifacts. Started as the Bulletin of the International Institute for Conservation-American Group (IIC-AG), in April 1961, the Journal matured into its current form in 1977. Since that time JAIC has become a repository for the core body of conservation information through its documentation of new materials, changing methods, and developing standards in the conservation profession. The four-color publication is distributed three times a year to AIC members and museum, library, and university subscribers.

Titanium dioxide helps protect the skin from both UVA and UVB rays. Plus, it’s generally considered to be safe for sensitive skin types. Not only that, but it might also make for sunscreens that are more suitable for children and infants since it’s much less likely to cause stinging compared to chemical sunscreens. And when used in foundations, titanium dioxide can even provide a little extra sun protection on top of your daily SPF.

What is HPMC?

Environmental and Safety Considerations

HPMC is produced through the etherification of cellulose, a natural polymer obtained from plant fibers. By introducing hydroxypropyl and methyl groups, HPMC exhibits unique solubility and viscosity properties. The degree of substitution of these groups influences its behavior in different applications. HPMC is generally soluble in cold water, forming transparent and viscous solutions, which makes it particularly useful in formulations requiring thickening or stabilizing agents.

Innovations and Future Prospects

Before beginning the dissolution process, it is essential to determine the desired concentration of HEC for your application. Commonly, HEC is dissolved in concentrations ranging from 0.5% to 2.0%. Keep in mind that higher concentrations may require more effort and time to dissolve completely.

The construction industry benefits from HPMC as well. It is commonly used in construction chemicals, particularly in the formulation of mortars and plasters. HPMC enhances the workability of these materials, allowing for easier application and smoother finishes. Additionally, it improves water retention in mortar mixtures, leading to better curing and bonding properties. This is especially crucial in harsh environments where evaporation rates are high.

Another important function of MHEC is its role as a binder. When added to mortar or cement-based products, it helps to bind the particles together, improving the overall cohesion and strength of the material. This is particularly crucial in applications where the products will be subjected to high loads or severe weather conditions, as it helps to prevent cracking and disintegration. Construction Industry Applications

4. Neutralization and Precipitation

Hydroxypropyl Methyl Cellulose Ether An Overview

In the personal care industry, HEC is used in a variety of products, including shampoos, lotions, and creams. The concentration of HEC in these formulations can affect the product's sensory characteristics, such as its feel and spreadability. Higher concentrations of HEC may be used in products that require a thicker consistency, such as hair styling gels, while lower concentrations are suitable for lighter formulations like facial moisturizers. Certain populations, including pregnant or breastfeeding women, the elderly, and individuals with underlying health conditions, should consult a healthcare provider before using products containing HPMC. While HPMC is generally recognized as safe, the effects can vary widely based on individual health status and dietary habits. For pregnant women, ensuring a balanced intake of nutrients is crucial, and excessive consumption of any thickening agent, including HPMC, could potentially lead to digestive complications that may affect overall health.

Hydroxyethyl cellulose (HEC) is a highly versatile polymer that has a wide range of applications in various industries. It is derived from cellulose, which is a natural polymer found in plant cell walls. HEC is modified with hydroxyethyl groups to enhance its properties, making it a highly effective thickening agent, stabilizer, and water retention agent.

Hydroxypropyl Methylcellulose (HPMC) is a versatile, non-ionic cellulose ether that has gained popularity across various industries, including pharmaceuticals, food, cosmetics, and construction. HPMC is produced in specialized factories that adhere to strict quality control measures to ensure the product's purity, consistency, and functionality. This article explores the significance of HPMC factories, the manufacturing process, and the wide range of applications of this remarkable polymer.

Im Laufe der Jahre wurden verschiedene Materialien erforscht, die einen guten Ersatz für Kapseln von Nahrungsergänzungsmitteln aus Gelatine bieten. Hydroxypropylmethylcellulose (HPMC) ist ein erfolgreiches Material für die zweiteiligen Kapseln. Es wird heutzutage auf der ganzen Welt verwendet.

The price of HPMC is influenced by a variety of factors, including raw material costs, production processes, market demand, and supply chain dynamics. As a result, the price of HPMC can fluctuate over time, impacting the cost of products that contain this compound. Manufacturers must carefully monitor HPMC prices to ensure that they can maintain competitiveness in the market while still achieving desired profit margins.

What is HPMC?

Environmental and Safety Considerations

HPMC is produced through the etherification of cellulose, a natural polymer obtained from plant fibers. By introducing hydroxypropyl and methyl groups, HPMC exhibits unique solubility and viscosity properties. The degree of substitution of these groups influences its behavior in different applications. HPMC is generally soluble in cold water, forming transparent and viscous solutions, which makes it particularly useful in formulations requiring thickening or stabilizing agents.

Innovations and Future Prospects

Before beginning the dissolution process, it is essential to determine the desired concentration of HEC for your application. Commonly, HEC is dissolved in concentrations ranging from 0.5% to 2.0%. Keep in mind that higher concentrations may require more effort and time to dissolve completely.

The construction industry benefits from HPMC as well. It is commonly used in construction chemicals, particularly in the formulation of mortars and plasters. HPMC enhances the workability of these materials, allowing for easier application and smoother finishes. Additionally, it improves water retention in mortar mixtures, leading to better curing and bonding properties. This is especially crucial in harsh environments where evaporation rates are high.

Construction Industry Applications

4. Neutralization and Precipitation

Hydroxypropyl Methyl Cellulose Ether An Overview

Certain populations, including pregnant or breastfeeding women, the elderly, and individuals with underlying health conditions, should consult a healthcare provider before using products containing HPMC. While HPMC is generally recognized as safe, the effects can vary widely based on individual health status and dietary habits. For pregnant women, ensuring a balanced intake of nutrients is crucial, and excessive consumption of any thickening agent, including HPMC, could potentially lead to digestive complications that may affect overall health.

Hydroxyethyl cellulose (HEC) is a highly versatile polymer that has a wide range of applications in various industries. It is derived from cellulose, which is a natural polymer found in plant cell walls. HEC is modified with hydroxyethyl groups to enhance its properties, making it a highly effective thickening agent, stabilizer, and water retention agent.

Hydroxypropyl Methylcellulose (HPMC) is a versatile, non-ionic cellulose ether that has gained popularity across various industries, including pharmaceuticals, food, cosmetics, and construction. HPMC is produced in specialized factories that adhere to strict quality control measures to ensure the product's purity, consistency, and functionality. This article explores the significance of HPMC factories, the manufacturing process, and the wide range of applications of this remarkable polymer.

Im Laufe der Jahre wurden verschiedene Materialien erforscht, die einen guten Ersatz für Kapseln von Nahrungsergänzungsmitteln aus Gelatine bieten. Hydroxypropylmethylcellulose (HPMC) ist ein erfolgreiches Material für die zweiteiligen Kapseln. Es wird heutzutage auf der ganzen Welt verwendet.

3. Food Industry In food applications, HPMC acts as a thickening agent and emulsifier, often enhancing textural properties in products like sauces, dressings, and gluten-free baked goods.

The viscosity of hydroxyethyl cellulose solutions is one of its defining properties. Viscosity refers to a fluid's resistance to flow; higher viscosity indicates a thicker fluid. HEC exhibits a non-Newtonian shear-thinning behavior, meaning its viscosity decreases under shear stress, making it easier to handle during processing and application.

The market for redispersible polymer powders has been growing steadily, driven by the expanding construction sector and the increasing demand for high-performance building materials. With urbanization and infrastructure development on the rise, RDPs are anticipated to play a crucial role in satisfying the complex requirements of modern constructions.

While HEC can dissolve in cold water, gentle heating can accelerate the process. If you choose to heat the water, do so to a temperature of about 60-70°C (140-158°F). Never boil the solution, as excessive heat can degrade the polymer.

In the pharmaceutical sector, hydroxyethyl cellulose plays a vital role as a binder in tablet formulations and as a drug release modifier. Due to its biocompatibility and non-toxic nature, HEC is widely utilized in various dosage forms, including gels, ointments, and controlled-release systems. It facilitates the uniform distribution of active ingredients, enhancing the bioavailability of drugs. Furthermore, HEC is often employed in eye drops and other ophthalmic preparations, facilitating sustained-release properties to enhance therapeutic effects.

In the realm of personal care products, MHEC is employed in formulations such as shampoos, conditioners, lotions, and creams. Its ability to enhance texture, provide a smooth feel, and stabilize emulsions make it a sought-after ingredient in cosmetic formulations. The pharmaceutical industry also benefits from MHEC, where it is used as a thickener and stabilizer in liquid formulations, ensuring the appropriate viscosity and homogeneity necessary for effective drug delivery systems.

Gelation temperature refers to the specific temperature at which a polymer, such as HPMC, transitions from a liquid to a gel-like state. This transition is crucial in applications where a stable gel is required, such as in drug delivery systems. The gelation process involves the swelling of HPMC molecules and the formation of a three-dimensional network that traps water, resulting in a semi-solid structure. Understanding and controlling the gelation temperature of HPMC can significantly impact its functionality in various products.

In the realm of personal care products, MHEC is employed in formulations such as shampoos, conditioners, lotions, and creams. Its ability to enhance texture, provide a smooth feel, and stabilize emulsions make it a sought-after ingredient in cosmetic formulations. The pharmaceutical industry also benefits from MHEC, where it is used as a thickener and stabilizer in liquid formulations, ensuring the appropriate viscosity and homogeneity necessary for effective drug delivery systems.

Where to Buy Hydroxyethyl Cellulose

The versatility of HPMC extends beyond just laundry detergents. It is also utilized in dishwashing liquids, all-purpose cleaners, and specialized cleaning products. By improving the effectiveness and user experience, HPMC contributes to a cleaner environment while also prioritizing safety for users and aquatic life.

The Versatile Uses of Hydroxyethyl Cellulose

- Hercules Chemical Co., Ltd. Known for its extensive range of cellulose derivatives, Hercules Chemical focuses on producing HPMC with varying viscosity grades to meet specific customer requirements.

Respiratory Issues

In the pharmaceutical sector, HPMC is paramount due to its role as a controlled drug release agent. It is often used in the formulation of tablets and capsules, enhancing bioavailability and ensuring a sustained release of active ingredients. Moreover, its solubility in cold water makes it an ideal binder and lubricant in tablet production.

Allergic Reactions

redispersible polymer powder market. Countries such as China, India, and Brazil are investing heavily in infrastructure projects, including residential, commercial, and industrial buildings, which require advanced construction materials to meet the growing demand. Redispersible polymer powders offer a cost-effective solution for enhancing the performance of construction materials, making them essential components in modern building projects.

4. Cooling the Solution Once the HPMC is fully dissolved, remove the container from heat and allow the solution to cool to room temperature. As it cools, the viscosity will increase, and the solution will become thicker.

How is Hydroxyethyl Cellulose Made?

hpmc 200000.

In the food sector, HPMC serves multiple purposes. It acts as a thickening agent to enhance the texture of sauces, dressings, and soups. Additionally, it is utilized as a fat replacer in low-fat and reduced-calorie foods, providing a creamy texture without the added calories. The ability of HPMC to form gels and stabilize emulsions also helps in extending the shelf life of products, ensuring that they retain their quality over time. Moreover, HPMC is non-toxic and has a low calorie count, making it suitable for health-conscious consumers.

In the construction sector, HPMC is employed as an additive in cement mortars, plasters, and tile adhesives. The cold water solubility of HPMC ensures that it can be easily mixed with water, allowing for improved workability and adhesion properties in construction materials.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has found extensive applications across various industries due to its unique properties. It is a water-soluble polymer derived from natural cellulose, modified to enhance specific characteristics such as viscosity, solubility, and film-forming abilities. HPMC is widely used in pharmaceuticals, food, construction, and personal care products, making it an essential ingredient in many formulations.

- Versatility The adjustable viscosity of HPMC allows formulators to tailor the characteristics of their products to meet specific requirements, making it suitable for a broad range of applications.